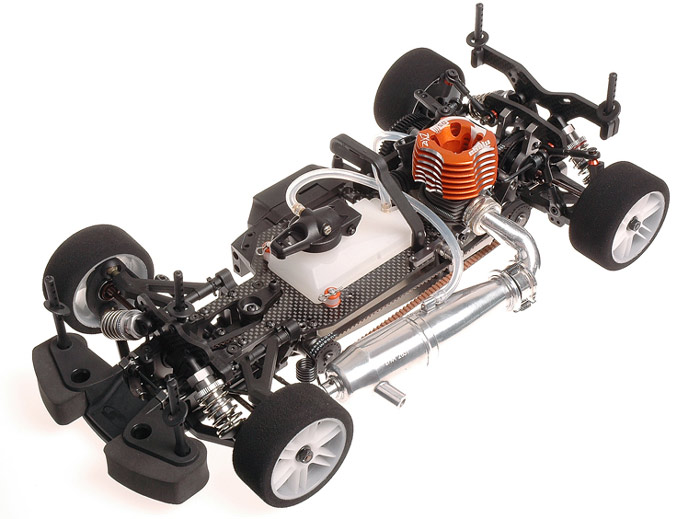

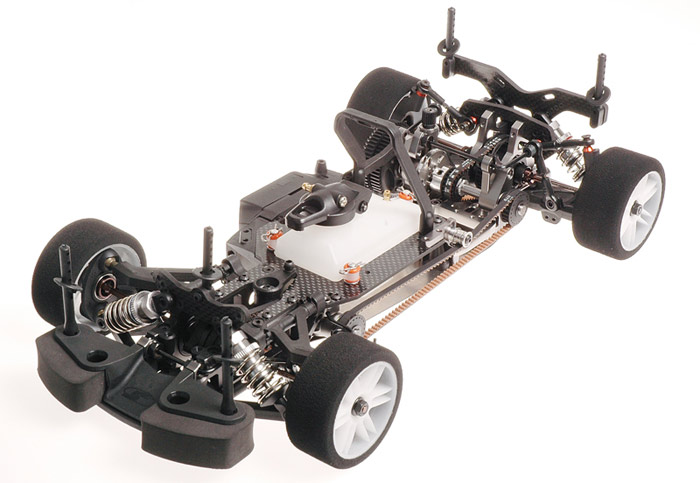

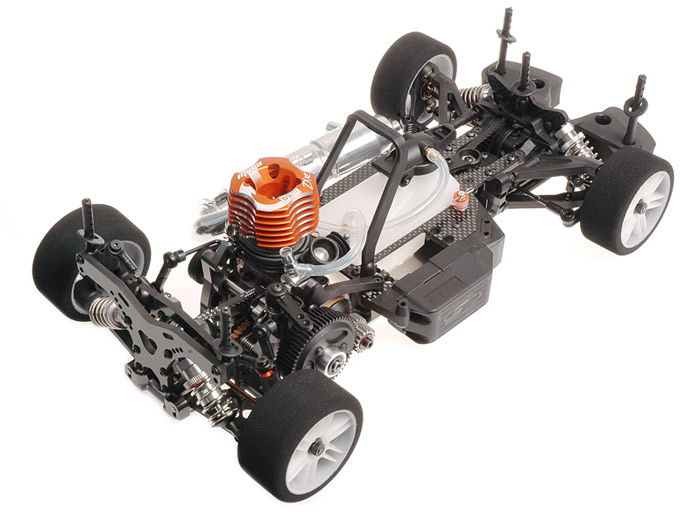

> Description Serpent 733, new design approachThe Serpent 733 has a new, very distinct open design and sets new standards in 1/10 scale race-chassis design. Serpent 733, new design approachThe Serpent 733 has a new, very distinct open design and sets new standards in 1/10 scale race-chassis design.

Many innovative and practical solutions are build into the unique design, to make assembly, set-up, racing and maintenance a joy !

GeometryNew geometry and roll-centers, lower center of gravity and modified weight-positioning for improved grip and better balance. GeometryNew geometry and roll-centers, lower center of gravity and modified weight-positioning for improved grip and better balance.

Adjustable caster, camber, toe-in, width, wheelbase front and rear, ride-height, roll centers and more.

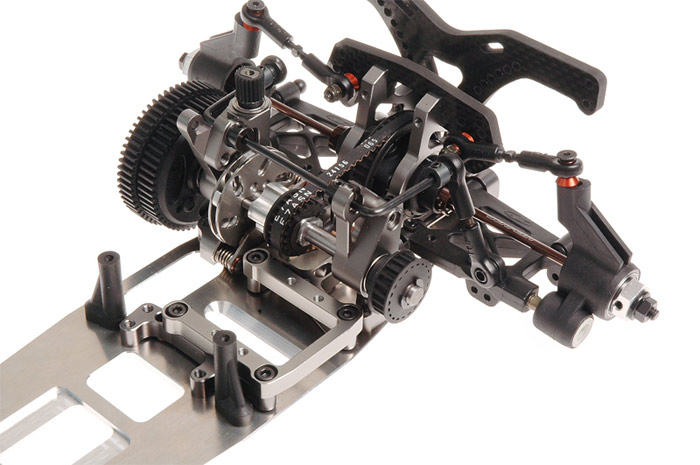

Front end bracketsAlu front lower bearing blocks and suspension brackets, with integrated anti-roll bar holders and integrated alu middle bearing block. The gear-diff is seated in eccentric nylon bushings to set the belt-tension. The right position ( choice of 4) of the eccentric bushings can be recognised from the outside, for easier re-assembly. The lower rear end brackets have steel pins pre-mounted which slide into the slots in the chassis, for precise positioning. Front end bracketsAlu front lower bearing blocks and suspension brackets, with integrated anti-roll bar holders and integrated alu middle bearing block. The gear-diff is seated in eccentric nylon bushings to set the belt-tension. The right position ( choice of 4) of the eccentric bushings can be recognised from the outside, for easier re-assembly. The lower rear end brackets have steel pins pre-mounted which slide into the slots in the chassis, for precise positioning.

Rear-end bracketsVery open design split type rear end assembly. The supersmall and light gear-diffs mount very low in the car, in precision machined split type alu brackets. The gear-diff is seated in eccentric nylon bushings to set the belt-tension. The right position ( choice of 3) of the eccentric bushings can be recognised from the outside, for easier re-assembly. Rear-end bracketsVery open design split type rear end assembly. The supersmall and light gear-diffs mount very low in the car, in precision machined split type alu brackets. The gear-diff is seated in eccentric nylon bushings to set the belt-tension. The right position ( choice of 3) of the eccentric bushings can be recognised from the outside, for easier re-assembly.

The lower rear end brackets have steel pins pre-mounted which slide into the slots in the chassis, for precise positioning.

The very open design leaves lots of space for maintenance, cleaning and cooling.

ChassisThe 3mm chassis is made of precision machined aerospace quality 7075 T6 alu. Countersunk and with chamfered edges. Some extra maching where needed for the belt, the engine with airscoop for cooling, for the flywheel and some extra space to allow the moutning the transpinder below the fueltank. ChassisThe 3mm chassis is made of precision machined aerospace quality 7075 T6 alu. Countersunk and with chamfered edges. Some extra maching where needed for the belt, the engine with airscoop for cooling, for the flywheel and some extra space to allow the moutning the transpinder below the fueltank.

The very closed design of the chassis creates the right level of rigidity in the car. More flex-control is offered with the chassis stiffner on the side and the ones on the chassis. A laser-angraved logo is the finishing touch.

Engine mountThe main upper engine mount is secured to the engine, and this bracket is then mounted to the 2 lower chassis-stiffners . The system allows for precise alignment of the clutch and 2-speed gearbox. Engine mountThe main upper engine mount is secured to the engine, and this bracket is then mounted to the 2 lower chassis-stiffners . The system allows for precise alignment of the clutch and 2-speed gearbox.

Chassis stiffners – flex controlThe main chassis-stiffner is the nylon one wich is mounted between the radioplate and the left 2-speed bracket. 2 machined alu chassis stiffners are placed on the chassis, below the engine. The rear one, with the longer legs, can be either fastened with just 2 of the 6 screws, or with 4 or all 6. The more screws are fastened the less flex will appear. Chassis stiffners – flex controlThe main chassis-stiffner is the nylon one wich is mounted between the radioplate and the left 2-speed bracket. 2 machined alu chassis stiffners are placed on the chassis, below the engine. The rear one, with the longer legs, can be either fastened with just 2 of the 6 screws, or with 4 or all 6. The more screws are fastened the less flex will appear.

Suspension frontNew front upper and front lower wishbones, made from superb nylon materials and have an excellent fit on the hardened steel pivot pins. The lower wishbones houses the hard-coated alu pivot-ball, which operates the front anti-roll bar. The wheelbase can be changed in the front by using the small caster-spacers in front or back of the lower front wishbone. In the top ofcourse change caster in the same way. The roll-center changes can be made by changing the inner pivot inserts for a lower, medium or higher position, depending on the situation. Suspension frontNew front upper and front lower wishbones, made from superb nylon materials and have an excellent fit on the hardened steel pivot pins. The lower wishbones houses the hard-coated alu pivot-ball, which operates the front anti-roll bar. The wheelbase can be changed in the front by using the small caster-spacers in front or back of the lower front wishbone. In the top ofcourse change caster in the same way. The roll-center changes can be made by changing the inner pivot inserts for a lower, medium or higher position, depending on the situation.

Front upper bracketThe nylon upper bracket, connect the front alu bearing blocks, holds the carbon fibre shocktower and the upper hinge pin inserts and incorporates the downstops. To take out the diff takes 4 screws only. Front upper bracketThe nylon upper bracket, connect the front alu bearing blocks, holds the carbon fibre shocktower and the upper hinge pin inserts and incorporates the downstops. To take out the diff takes 4 screws only.

SteeringblocksThe kit comes with the strong prooven steeringblocks of the 720, with off-set 0. Offset 1 is available as option. SteeringblocksThe kit comes with the strong prooven steeringblocks of the 720, with off-set 0. Offset 1 is available as option.

The steeringblocks mount to the wishbones with light-weight coated alu 8.5mm pivotballs, and use the nylon ball-cups for an ultra light and ultra smooth suspension process

Anti-roll bar frontBall-raced wire type front anti-roll bar system, more efficient and easier to tweak. Operated by linkages that mount to alu pivotballs on the ower front arms. Anti-roll bar frontBall-raced wire type front anti-roll bar system, more efficient and easier to tweak. Operated by linkages that mount to alu pivotballs on the ower front arms.

2.5mm is standard, 3 other options. 1.8-2.0, 2.2 and 2.8

Shocktower frontCarbon fibre front shocktower in 3.2mm with 3 positions for the front shocks. Includes holes to mount the 3rd bodymount. Shocktower frontCarbon fibre front shocktower in 3.2mm with 3 positions for the front shocks. Includes holes to mount the 3rd bodymount.

ShocksPre-assembled RCCX shock-sets. Short type both front and rear, also short springs front and rear. With the 2009 modification on rod-support and silicone x-ring for supersmooth shocks. SS-steel shock-rods, precision machined coated shock-housings, foam bleeders, precision moulded nylon pistons and shock-parts. The spring pre-load nut has a silicone o-ring inside to prevent unwanted change. ShocksPre-assembled RCCX shock-sets. Short type both front and rear, also short springs front and rear. With the 2009 modification on rod-support and silicone x-ring for supersmooth shocks. SS-steel shock-rods, precision machined coated shock-housings, foam bleeders, precision moulded nylon pistons and shock-parts. The spring pre-load nut has a silicone o-ring inside to prevent unwanted change.

Use 1000 Cst (40W) shock-oil as enclosed for standard set-up both front and rear.

Gear-differential.Extremely small and light gear differential, seated as low as possible in the 733. The same gear-diff is used in the front and rear of the car, just different pullies are mounted. High quality, precision machined , hardedned gears, combined with SS-steel shafts, create a supersmooth gear-diff. The gear-cases are sealed with a captured o-ring. The SS-steel precison machined outdrives are lightened to decrease rotating mass further. For standard set-up use 80.000 Cst front and 30.000 Cst rear oil, as provided. Gear-differential.Extremely small and light gear differential, seated as low as possible in the 733. The same gear-diff is used in the front and rear of the car, just different pullies are mounted. High quality, precision machined , hardedned gears, combined with SS-steel shafts, create a supersmooth gear-diff. The gear-cases are sealed with a captured o-ring. The SS-steel precison machined outdrives are lightened to decrease rotating mass further. For standard set-up use 80.000 Cst front and 30.000 Cst rear oil, as provided.

Its very easy and fast to take the diffs out of the car.

CentaxThe Serpent 733 comes with the famous Centax clutch ( an original Serpent innovation) . The ultra reliable Centax III WC version comes with precison machined, hardcoated alu screw on gears ( laser engraved) mounted on a hardened steel clutch-bell.

A very small and light 31mm hardcoated alu flywheel with precision mounted steel pins. Race developed clutch shoe and flyweights, combined with a hard Centax spring, to create a superb working clutch for amazing accelleration and durability.

Ball-jointsHigh quality nylon ball-joints for precision fit on the pivot balls. All balljoints of the car are on one larger frame inside the kit. Some have TOP as indication, to show which direction to mount them for best operation. Ball-jointsHigh quality nylon ball-joints for precision fit on the pivot balls. All balljoints of the car are on one larger frame inside the kit. Some have TOP as indication, to show which direction to mount them for best operation.

GearboxUlta smooth gear-changes are provided by the WC type Light-Compact (LC) automatic 2-speed gearbox, which combines perfectly with the Centax III-WC system.

Precision machined 2-speed bell and one-way adaptor, combined with durable centrifugal shoes mounted on the SS-steel polished adaptor. Balanced SS-steel 2-speed layshaft. |